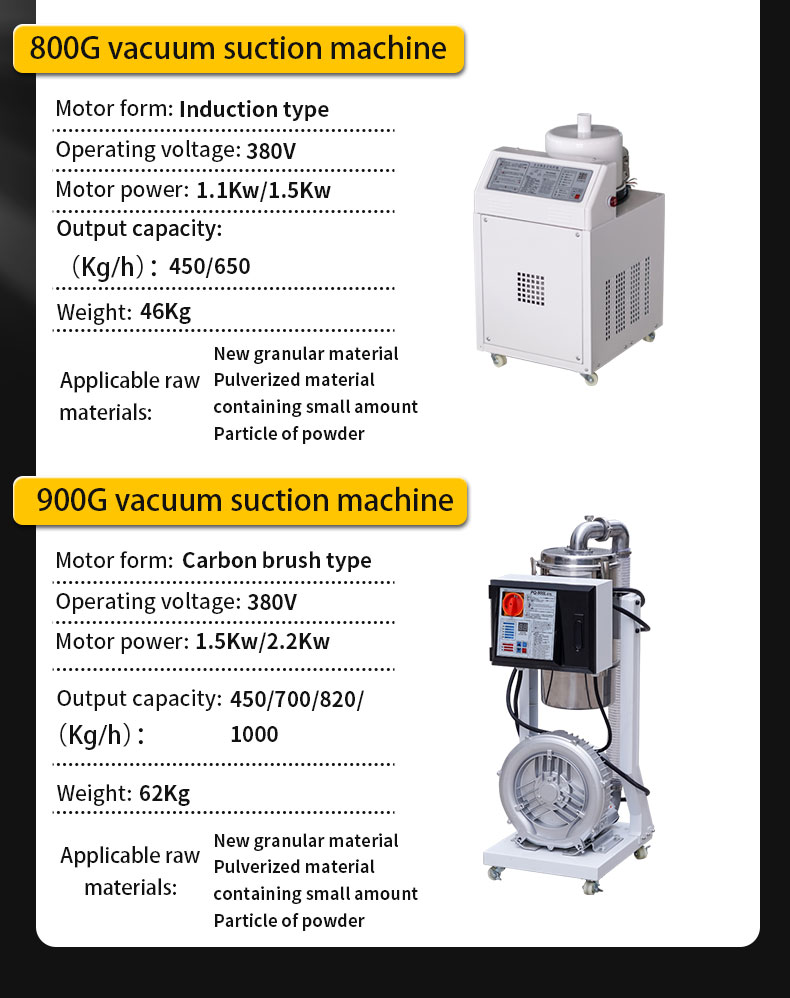

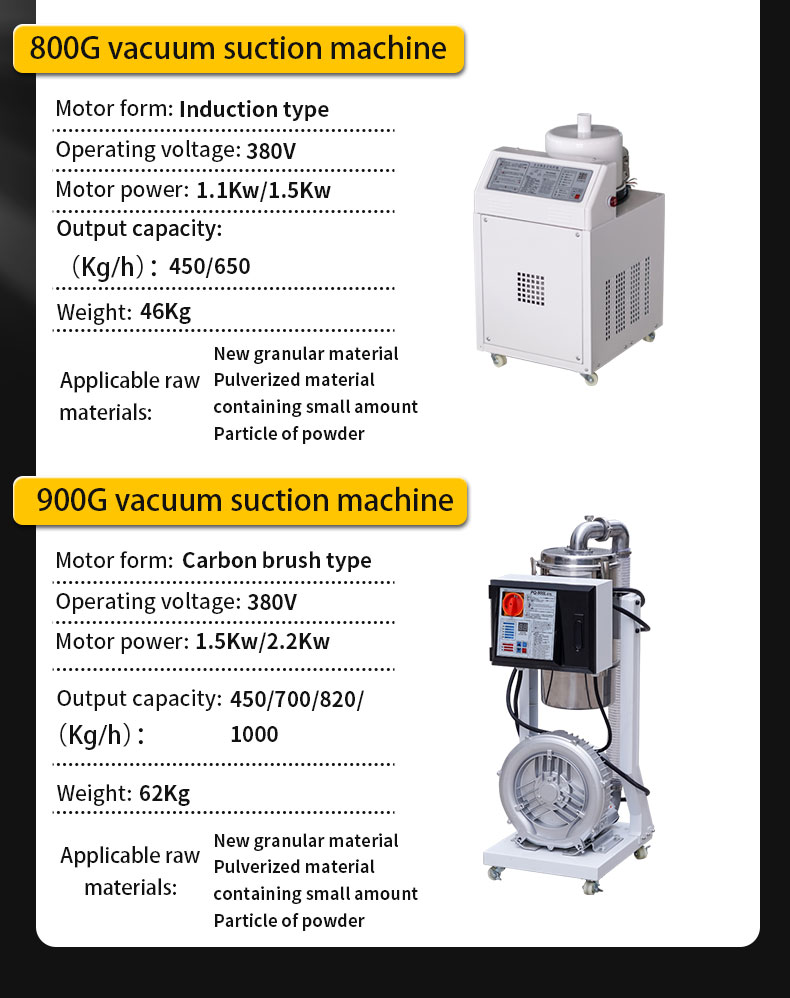

850G suction machine

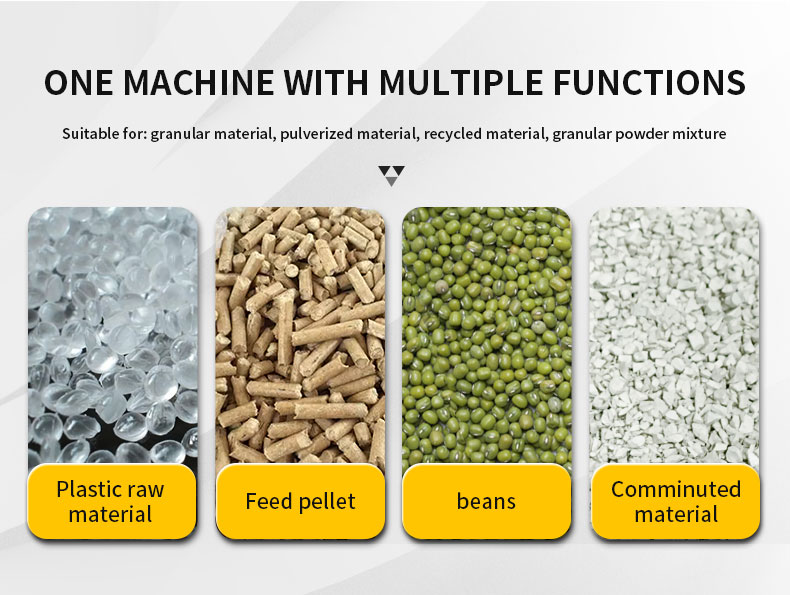

The 850G Vacuum Conveyor is an efficient automation machine designed for the conveying of raw materials in industrial production. Its powerful suction power of 850G enables it to quickly and reliably absorb a variety of powdery and granular materials, and is widely used in raw material handling and transportation in plastics, chemical, pharmaceutical and other industries. This equipment not only improves production efficiency, but also reduces labor costs, bringing significant economic benefits to the enterprise.

The core technology of this vacuum conveyor lies in its efficient vacuum pump and intelligent control system. The vacuum pump is able to generate a strong negative pressure in a short period of time, thus effectively sucking up and conveying materials. The intelligent control system allows users to customize the suction speed and time according to different material types and conveying needs, ensuring that the best results are achieved every time. In addition, the equipment is equipped with high-performance filters, which can effectively prevent material leakage during the conveying process and keep the working environment clean and tidy.

In terms of design, the 800G vacuum conveyor emphasizes user-friendliness. The equipment is compact, takes up little space, and is easy to install and maintain. The simple and intuitive operation interface allows even operators with no professional background to get started quickly. At the same time, the durable materials and robust structure of the equipment ensure its stable operation in harsh environments, which greatly reduces the failure rate and maintenance costs.

Overall, the 850G vacuum conveyor has become an indispensable piece of equipment in modern industrial production due to its excellent performance, flexible operation and efficient material handling capacity, providing strong support for the production efficiency and product quality of enterprises.

Key Features:

1. Exclusive Customization:

We will tailor different Model vacuum suction machine for you according to the needs of customers, and the price required for different Model number will be different.

2. Efficient suction technology

The advanced vacuum suction system can quickly and stably transfer materials from one place to another, greatly improving production efficiency.

3. Unique separation design

The separated structure ensures that the material is not contaminated during the transmission process, maintaining the purity of the raw material, and is suitable for the high-standard production needs of various industries.

4. Durable and reliable materials

It is manufactured with high-quality materials to ensure that the equipment has excellent wear resistance and corrosion resistance, prolong the service life of the equipment, and reduce maintenance costs.

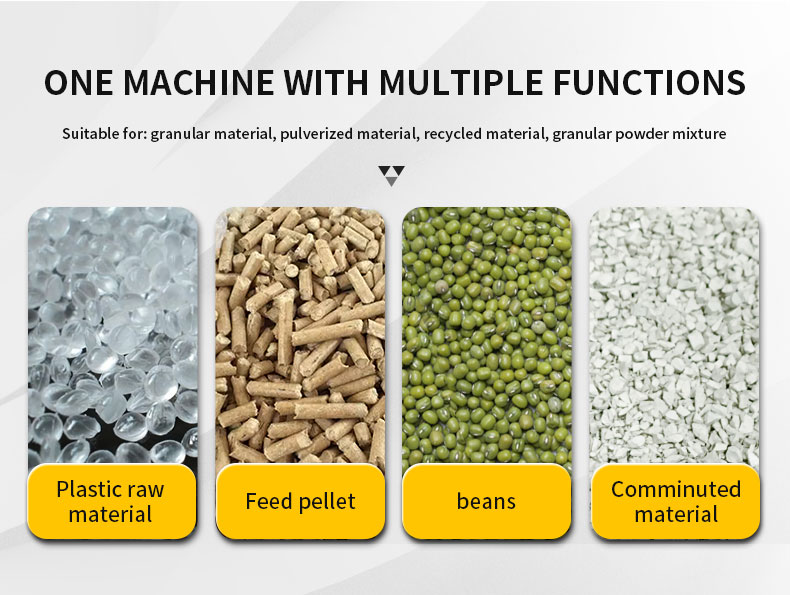

5. Flexibility and adaptability

The design is flexible, can be applied to a variety of materials and different working environments, to meet the individual needs of customers, and easily cope with various production challenges.

FAQ

1) Are you manufacturer?

Yes, we are manufacturer over 10 years' experience.

2) How can I place order?You can contact us by email about your order details, or place order online.

3) What's the order procedure?We issue you Proforma Invoice after you confirm the order. And then You make the payment for the deposit before we go into production.It usually takes 7-15 days for production. We will contact you for shipment details and the balance payment when the machine is ready. After payment has been settled, we will ship out the machine.

4) How can I pay you?You can make payment by T/T (telegraphic transfer) ,Western Union,Moneygram and L/C.

5) Do you have manual with the machine?Yes, of course. It is in English version. We will send it with the machine.

6) Can you offer us the necessary paper to do the customs clearance?Yes, of course. We will send you all paper you need.